In today’s competitive market, businesses increasingly rely on advanced digital tools to streamline workflows, reduce risks, and improve decision-making. Among the most transformative innovations is laser scanning technology, offering unparalleled precision in capturing real-world conditions.

- Transforming Data Acquisition Through High-Accuracy Scanning

- Practical Applications Across Many Industries

- Enhanced Efficiency, Lower Costs, and Actionable Insights

Companies across various industries now use this cutting edge technology to accelerate planning, enhance quality, and ensure every project meets strict quality standards.

Transforming Data Acquisition Through High-Accuracy Scanning

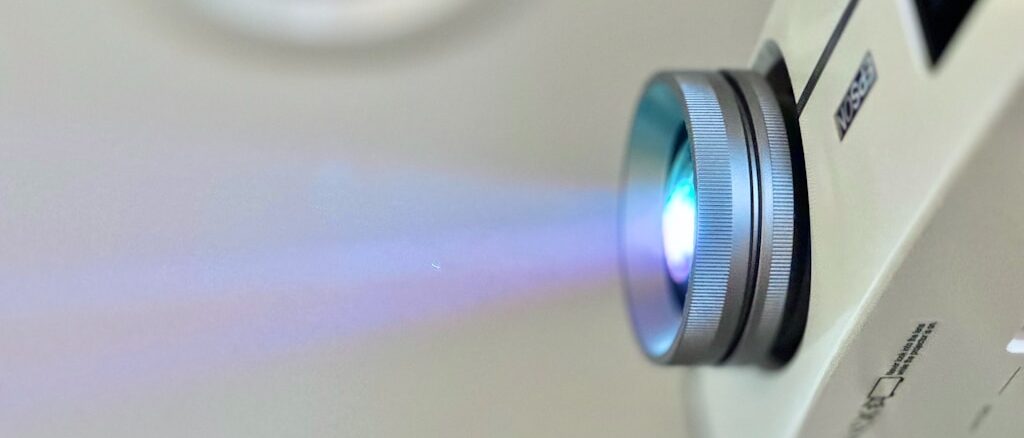

Modern businesses depend on fast and reliable data acquisition, and 3d laser scanning has become an indispensable tool for gathering a dense set of data points from existing structures, equipment, or vast landscapes. Using laser scanners, which emit laser beams and detect the returning signal through light detection and precise distance calculation, companies can capture highly detailed information about an object’s surface or an entire site.

Whether using phase shift systems or time of flight systems, each single pulse of emitted laser light helps create a highly detailed point cloud that can be further used for analysis, modelling, or integration with bim software and photogrammetry software. Businesses benefit from rapid data, high accuracy, and accurate results, significantly reducing time consuming manual measurements.

Practical Applications Across Many Industries

Laser scanning services support construction, engineering, manufacturing, and facility management by providing accurate data essential for planning and performance. In architectural and engineering design, 3D scanner outputs capture data that aligns with design specifications, ensuring the primary goal of delivering structures that match intent from concept to end point.

Companies can integrate 3d scanning into construction projects for clash detection, installation verification, and project management, while quality inspection and quality control benefit from analyzing intensity patterns and deviations in geometry.

Beyond construction, industries use scanning for reverse engineering, forensic investigations, historical preservation, and documentation of cultural landmarks. The resulting reality capture supports long-term planning and protects valuable heritage.

Enhanced Efficiency, Lower Costs, and Actionable Insights

Using laser scanning and 3d laser scanners enables businesses to provide accurate data not only faster but more economically. These cost effective solutions reduce rework, minimize errors, and help teams avoid costly surprises on-site. By combining laser pulses with advanced data processing, companies turn raw data into actionable insights that improve coordination between teams and streamline related services such as space planning, modelling, and engineering design.