When manufacturing conversations move beyond capacity and cost, they start circling around something harder to quantify: control. Control over heat, over materials that don’t naturally cooperate, over timelines that no longer tolerate waste. This is where precision microlayer joining quietly steps in.

The transition from “standard” manufacturing to micro-welding is not just a technical upgrade; it is a fundamental survival strategy for modern industry because industrialization has entered an era where material costs, miniaturization, and sustainability have converged to create a “perfect storm.”

1. Microscopic Laser Welding: Precision That Scales Without Fragility

If you’re responsible for growth; whether as an investor, engineering leader, or operations head—laser welding answers a specific fear: What breaks when we scale? Industrial Laser Welding exists to ensure quality is a fixed constant defined by extreme thermal control.

Its defining advantage is thermal discipline. Energy is applied so narrowly that surrounding material barely registers a temperature rise. That’s not a technical curiosity—it’s what allows sensitive assemblies to survive.

Where it becomes indispensable:

- Medical assemblies where internal batteries and electronics sit millimeters from the weld

- Micro-electronics that rely on ultra-thin conductors without insulation damage

- Hermetic enclosures that must remain moisture- and gas-tight for years

CNC-programmable laser systems turn precision into a repeatable language. What once depended on a master technician’s hand becomes a documented, validated process. The result isn’t just throughput—it’s confidence. Production shifts from something that feels brittle into something that can absorb growth without surprises.

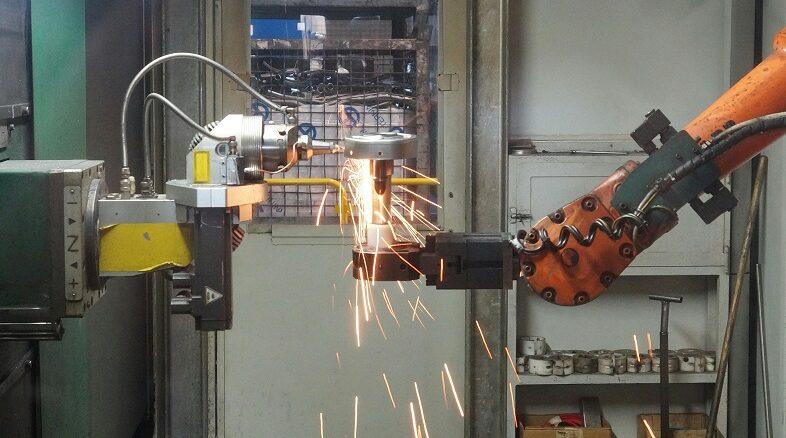

2. Percussion Welding: When Materials Refuse to Play Nice

Modern engineering is full of bad material relationships. Copper and stainless. Titanium and nickel alloys. They don’t want to bond; but performance demands they do. Welding dissimilar metals doesn’t give room for guesswork. It requires tech where the joint happens in milliseconds—before heat can create brittle intermetallic layers that doom the connection later. No slow burn. No structural regret.

Whether you’re working with EV batteries or medical sensors, well-designed Production Welding solves both the material science challenge and the throughput demands of modern manufacturing. It replaces slow, multi-step processes like crimping or soldering with a single, sub-second impact that integrates seamlessly with robotic automation.

Why this matters in the real world:

- Aerospace sensors that face extreme temperatures without added weight

- EV battery connections that stay efficient without cooking chemistry

- Assemblies that lose fasteners, inserts, and unnecessary complexity

From a business angle, this is rare territory: higher performance and simpler supply chains. Less mass. Fewer parts. Fewer things that can fail quietly.

3. Microscopic TIG Welding: Restoring Value Instead of Replacing It

There are moments when innovation isn’t the priority—continuity is. A chipped mold, a worn edge, a damaged feature on a six-figure tool doesn’t require reinvention. It requires restraint and precision. That’s where microscopic TIG welding by a reputable welding company like Micro Weld becomes a game changer for your manufacturing reputation.

Unlike laser, TIG is additive by nature. It doesn’t just join; it rebuilds. Material is placed exactly where failure occurred, under magnification, without disturbing the rest of the asset.

This matters when:

- A hardened tool steel shut-off fails mid-production

- Non-ferrous components suffer localized wear

- Engineering changes must be applied to existing tooling

Micro TIG also excels with materials that resist laser efficiency, particularly aluminum and copper alloys. With micro-welding, you don’t wait for the tool to “die”, you use targeted restoration to rebuild microscopic wear as it happens, thus extending the useful life of your machines and safety. It’s not just repair—it’s preservation of momentum.

4. Hybrid Additive Finishing: Fixing What 3D Printing Can’t Admit

Metal 3D printing promised freedom—and delivered new kinds of failure. Porosity. Surface inconsistencies. Inspection fallout. Too many teams quietly eat the cost of scrapped prints.

Hybrid additive finishing is the grown-up response.Instead of pretending printers can do everything, micro-laser and micro TIG step in after the print to do what printers can’t. With such advanced welding solutions, it represents the “state of the art” in high-end additive manufacturing (AM) for 2026.

What that unlocks:

- Sealed surfaces on printed titanium implants

- Fine features added where powder resolution falls short

- Internal defects corrected without reprinting the entire part

This isn’t a workaround—it’s a strategy. Print for form. Weld for precision. The result is fewer rejects, lower total cost, and parts that actually pass scrutiny instead of looking good in CAD.

5. From Workshop to Balance Sheet: Precision as a Financial Decision

Here’s the part most teams miss: welding choices show up in financial statements, not just shop floors.

- Laser welding isn’t about elegance—it drives cost per unit down through consistency.

- TIG welding isn’t nostalgia—it delays capital replacement.

- Percussion welding reduces complexity before it becomes overhead.

- Hybrid finishing protects additive investments from becoming sunk costs.

In a world shaped by inflation, logistics risk, and material volatility, “repair over replace” isn’t a slogan, it’s survival math. Combine these technologies correctly and you don’t just make parts. You protect momentum. What you’re buying isn’t a weld—it’s continuity when conditions stop being friendly.

In essence, precision microlayer joining operates in a different “frequency” than traditional heavy industry. While standard welding involves the “noise” of sparks, massive heat distortion, and high-decibel arcs, micro-welding operates with a level of control that eliminates the “chaos” of manufacturing. It just quietly prevents failure. It stretches asset life, stabilizes scale, and lets advanced designs exist without apology. For organizations that take manufacturing seriously, this isn’t a tactical choice, it’s a philosophical one. It says you value expertise over shortcuts, systems over luck, and decisions that hold up long after the pressure is gone.