The role of welding in industrial component production is no longer a contest of number of orders. In the modern era, the success of welding metrics has been replaced by technical yield and strategic enability. The manufacturing results that win are not the loudest or the largest — they are the most disciplined welding techniques and processes.

Expert welders understand materials at the microscopic level, intervene with intention, and treats every weld not as a task, but as a strategic decision that determines safety, lifespan, compliance, and brand reputation. If you’re an investor, plant director, or product innovator, this is where your real leverage now lives — in specialized welding strategies that quietly determine whether a design survives industrial reality.

1. The Hermetic Barrier: Implantable Med-Tech

When you mass-produce pacemakers or neuro-stimulators, you are not assembling hardware. You are manufacturing trust. These devices must remain leak-proof inside the human body for 20+ years. Moisture ingress is not a defect — it’s a catastrophic liability.

The intervention is simple in theory, brutal in execution:

Weld titanium or platinum housings with zero margin for error while protecting delicate internal AI circuitry. In such high-stakes production needs, pulsed Industrial Laser Welding delivers precision timing and calibrated penetration depth.

The strategy makes this possible:

- Discrete pulses deliver controlled energy.

- Heat never migrates to internal batteries or sensors.

- The seal remains hermetic, clean, and regulator-ready.

For manufacturers operating under ISO 13485, this is not optional. It protects compliance, patient safety, and brand credibility simultaneously. When you master hermetic sealing at scale, you stop being a supplier. You become a long-term medical technology partner.

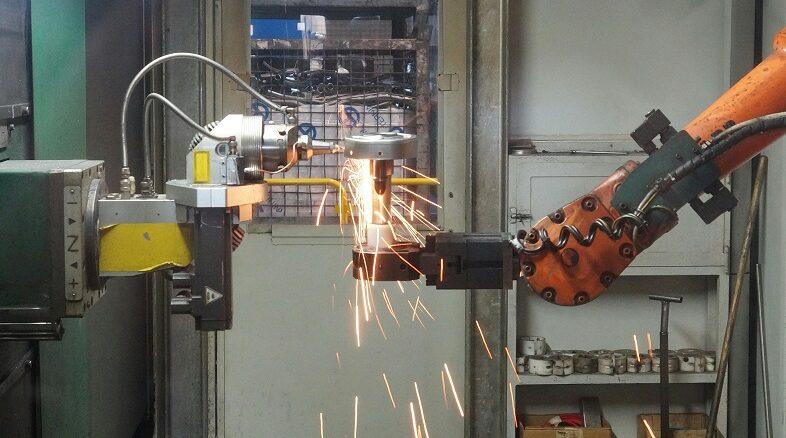

2. The Multi-Metal Junction: EV Battery Busbars

Electric vehicles are not limited by design — they’re limited by joining copper and aluminum at scale. These metals resist traditional methods, reflecting energy and forming brittle compounds. If you’re scaling EV production, your bottleneck isn’t marketing. It’s metallurgy. That’s where Production Welding Services become the quiet force behind battery safety, reliability, and performance longevity. While a consumer only sees the battery’s capacity or charging speed, those metrics are entirely dependent on thousands of microscopic, perfect welds hidden inside.

The intervention:

Connect thousands of cells to busbars in seconds — reliably, repeatedly.

The strategy: Adjustable Ring Mode (ARM) with Beam Oscillation.

- The outer ring pre-heats reflective copper.

- The core beam performs the weld.

- Oscillation “stirs” the metals, preventing brittle intermetallic formation.

The outcome isn’t just conductivity. It’s durability — joints that survive vibration, thermal cycling, and years of road stress.

- For investors, this is yield stability.

- For manufacturers, it’s warranty protection.

- For energy markets, it’s scalable electrification.

3. Structural Weight-Loss: Aerospace Thin-Wall Fabrication

In aerospace, grams matter. Remove weight, and you reduce lifetime fuel costs. Multiply that across fleets, and it becomes a strategic advantage. But welding ultra-thin Inconel or titanium heat exchangers? One wrong move and the part warps beyond recovery.

The intervention: Join walls as thin as .005” without distortion.

The strategy: Keyhole Mode Welding.

- A focused laser creates a vapor tunnel.

- Penetration is deep but extremely narrow.

- Heat-affected zones remain minimal.

This isn’t brute-force joining. It’s surgical penetration.

The result? Structural integrity without deformation — allowing aerospace engineers to pursue aggressive lightweight designs without fear of production scrap.

If your business lives in aviation, precision is not aesthetic — it’s economic survival.

4. Zero-Friction Assembly: Consumer Electronics Micro-Connectors

In consumer electronics, production speed is measured in fractions of seconds. But microscopic wires — sometimes .0015” in diameter — leave no room for human inconsistency.

Manufacturing intervention:

Attach micro-wires to chips smaller than a grain of dust — thousands of times per shift.

The Welding Strategy: CNC Automated Micro-Laser Welding.

- AI-driven path tracking removes variability.

- High-speed imaging confirms placement accuracy.

- The laser repeats exact movements at sub-second intervals.

This eliminates the “human variable” without eliminating craftsmanship — because expertise still defines system calibration and process control.

The reward? Ultra-high throughput with near-zero rejects.

For electronics manufacturers, that’s not efficiency — it’s market dominance.

5. Infinite Life-Cycle: Tool and Die Revitalization

A $100,000 injection mold chipped in one corner should not trigger a six-month overseas replacement delay. Yet that’s still how many factories operate.

Forward-thinking production plants see tooling differently.

Production process intervention: Restore worn stamping dies or injection molds in-house within 24 hours.

The strategy: Micro-Laser Material Build-Up.

- Metal is added layer by layer with microscopic control.

- Hardness can exceed original OEM specifications.

- Only damaged zones are treated — not the entire tool.

This is circular manufacturing in action. That way you achieve:

- You reduce capital expenditure.

- You minimize downtime.

- You extend asset lifespan.

If sustainability matters to your investors, revitalization strategies are no longer optional — they’re financial intelligence.

6. The Art and Science of Invisible Architecture: Luxury Retail and Interior Facades

Luxury brands don’t tolerate visible fasteners. They demand monolithic surfaces — glass and metal appearing as a single continuous form.

The intervention: Create structural strength without aesthetic disruption.

The strategy: Deep-Penetration Backside Micro-Welding.

- Structural joints are formed from the inside or rear surfaces.

- Weld beads remain microscopic.

- Grinding and polishing are eliminated.

- Labor costs drop — sometimes by 60%.

- Finishing timelines shrink.

- Design freedom expands.

For developers building high-profile retail spaces or architectural landmarks, this is not cosmetic. It’s brand alignment. Precision welding here becomes invisible craftsmanship — the kind that elevates entire spaces without announcing itself.

In essence, outsourcing your welding needs becomes a critical industrial leverage. Mass production in 2026 is defined by intervention, not repetition. The companies that lead are those that apply specialized welding strategies exactly where materials resist, where compliance tightens, and where design meets risk.

If you’re building the next generation of devices, vehicles, aircraft, or infrastructure, your competitive advantage will not be labor cost alone. It will be the depth of technical expertise guiding each microscopic decision.

Because in this era, production is no longer about doing more.

It’s about doing it with intent.