How Illinois Manufacturers Are Using Advanced Welding to Cut Costs, Reduce Scrap, and Increase Sustainability

August 6, 2025: In 2025, Precision Welding for Material Efficiency in Illinois is more than a technical improvement—it’s a strategic shift. With rising material costs, tighter environmental regulations, and the growing need for smarter production, Illinois manufacturers are turning to advanced welding systems to reduce waste, streamline operations, and increase profitability. Whether it’s heavy machinery in Peoria or EV production in Normal, this trend is reshaping how the Prairie State welds.

What Is Precision in Welding?

Precision in welding refers to the controlled application of heat and filler material to produce high-quality, defect-free joints with minimal waste. Precision welding systems allow manufacturers to control:

Bead geometry

Heat input

Weld depth and width

Real-time joint tracking

Filler material usage

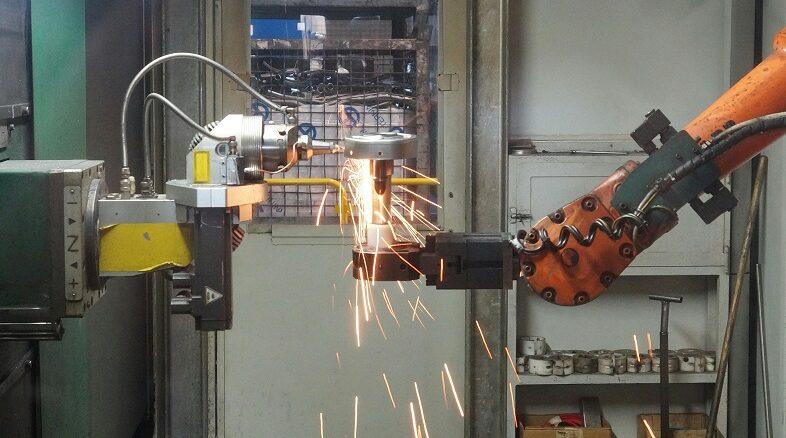

In 2025, factories in Illinois use robotic arms, laser-guided tools, and AI-assisted sensors to ensure perfect welds—especially critical in aerospace, transportation, and energy equipment where consistency equals safety.

The Waste Problem in Traditional Welding

Before precision systems became mainstream, Illinois manufacturers commonly faced:

Overwelding (adding unnecessary material)

Heat distortion (leading to part rejection)

Rework due to misalignment or porosity

Higher use of consumables (e.g., gas, tips, filler)

These issues led to lost materials, increased costs, and missed sustainability targets. As Illinois tightens its environmental standards through the IEPA (Illinois Environmental Protection Agency), the shift to precision welding for material efficiency in Illinois is a practical necessity.

How to Increase Welding Efficiency

In 2025, Illinois facilities are increasing welding efficiency by:

Automating repetitive welds using CNC-controlled MIG/TIG systems

Reducing heat input via laser and hybrid welding technologies

Minimizing filler use with friction stir welding (FSW)

Detecting defects early using AI-powered inspection cameras

These upgrades lead to shorter production cycles, lower energy consumption, and minimal rework—boosting throughput while keeping material costs in check.

What Is the Most Efficient Welding Process?

Based on industrial usage in Illinois, the most efficient welding processes in 2025 are:

Laser Beam Welding (LBW): Ideal for EV frames and high-strength steel, offering deep penetration with minimal heat distortion.

Friction Stir Welding (FSW): Great for lightweight aluminum parts in aerospace and battery casings, with no filler metal needed.

Robotic MIG Welding: Fast, scalable, and now widely used in agricultural and construction equipment manufacturing.

These technologies are helping Illinois manufacturers reduce material waste by as much as 30% per unit.

What Is the Efficiency of the Welding Process?

Welding efficiency includes both thermal efficiency and operational efficiency:

Thermal Efficiency:

SMAW: 30–40%

MIG/GMAW: 60–80%

Laser & FSW: Up to 95%

Operational Efficiency (in 2025 Illinois plants):

35% increase in first-pass yield

25% lower energy use per weld

50% reduction in rework and scrap

These numbers reflect the impact of precision welding for material efficiency in Illinois as more companies deploy smart manufacturing systems.

Case Studies from Across Illinois

Caterpillar (Peoria):

Upgraded to robotic weld cells for structural frames—resulting in a 22% reduction in steel waste.

Rivian Automotive (Normal):

Using laser welding in EV body frames, reducing aluminum use per unit by over 15%.

Rockford Aerospace Cluster:

Adopted FSW for jet engine components, delivering consistent welds with zero porosity and virtually no scrap.

These examples underscore how precision welding directly supports Illinois’ sustainability and industrial growth goals.

Environmental and Economic Impact

By switching to precision welding, Illinois manufacturers gain:

Lower raw material consumption

Reduced emissions from metal cutting and rework

Safer working environments with less spatter and fume

Compliance with local green manufacturing initiatives

Eligibility for clean energy and innovation tax credits

This makes precision welding for material efficiency in Illinois not just a cost-saving measure, but a competitive and environmental differentiator.

Conclusion

In 2025, Precision Welding for Material Efficiency in Illinois is driving the future of manufacturing. From heavy equipment to EVs, manufacturers are seeing tangible gains in quality, speed, and sustainability. As more companies invest in automation, AI, and clean welding technologies, Illinois is on track to become a national leader in smart, waste-free production.